Some of us may possibly keep in mind the bracing and virtuous feel of brushing our teeth or washing our confront with pastes that appeared to have a pinch of seashore sand or salt did not we come to feel cleaner than cleanse?

Well, remembering is all that’s left. Those toothpastes and skin scrubs did their do the job with small beads of plastic, extremely little and poorly comprehended pollutants that are transferring by the tons into waterways, soil, animals, food items, and our own bodies.

The Microbead-Free Waters Act of 2015 banned all those little plastic beads from exfoliating scrubs and toothpastes, but that smaller motion is just a seize at the cheapest-hanging fruit of a world wide issue. The environmental danger of microplastics — designed primarily by the breakdown of plastic squander — continues. In the earlier ten years, researchers are performing harder to capture, evaluate, and consider the danger of microplastics in spots like Narragansett Bay.

Also, microplastic fibers, a worrisome subset of microplastics, have caught the interest of the textile field, which brings the fibers into currently being, which now would like to discover strategies to seize and reuse them.

Microplastic is outlined as any bits of plastic up to 5 millimeters in dimensions. They can be spherical, jagged, or any random shape. They are made by the bodily and chemical breakdown of plastic squander, and are located everywhere on Earth, which include the depths of the oceans, on mountaintops, and in the flesh of animals and breast milk of humans.

It is believed that 44{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} to 50{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} of sea birds, sea turtles, otters, and fish have eaten or been entangled in plastic particles. Analysis is looking at the inner injury to animals, especially sea life, that ingest plastic, and to the people who take in the animals that have plastic in their bodies. A similar problem is whether or not microplastics in the setting act as a vector to absorb and transmit microorganisms.

Microfibers are defined as small slivers of materials with a 1:3 ratio of width to length. Fibers are “shed,” or thrown off, textiles in the course of the straightforward movements of employing, putting on, and washing them. In addition to clothing, textiles can involve towels and linens, sails and rope, cigarette filters, confront masks, and tire tread.

Pure fibers, these types of as cotton, linen, wool, and silk, lose their fibers, as do polyester, rayon, acetate, and all of the other mixes of synthetic fabrics that originate in an oil effectively.

Gurus estimate that about 9 million metric tons of plastic enter the world’s oceans each individual yr, in accordance to Outside of Plastics. About 85{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} of microplastic squander in the atmosphere is thought to be microfibers. About 100 million tons of textiles was manufactured across the globe in 2016, mentioned Martin Bide, retired professor from the Division of Textiles, Vogue Merchandising and Design and style at the College of Rhode Island. Also in that calendar year, he explained, 62.7{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} of the worldwide fiber current market was polyester fibers.

As researchers troll the Earth’s waters for microplastics to document and review, individuals in the textile, manner, and style industries are hoping to arrive up with strategies to obtain squander plastic and, mentioned simply just, to soften and then spin the plastic into filaments and fibers that are then employed to weave new cloth.

This do the job to retrieve and reuse junk plastic is a variation of the reduce, recycle, refill, and reuse mantra that is aimed now at all kinds of throwaway supplies.

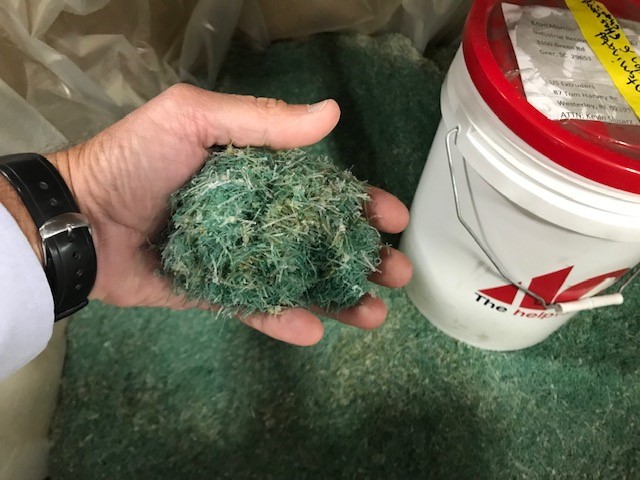

Microfibers, from natural resources like cotton and petroleum-primarily based components like polyester, enter the surroundings in a dizzying wide range of approaches, some more clear than other individuals. All through ordinary use and motion of garments, sails, rope, and even cigarette butts, the fibers are lose into the setting. Fabrics that are tightly woven, with lengthier fibers, will get rid of a lot less and much more slowly. Quick, loose-weave fibers shed more quickly. In the globe of microplastic fibers, just one of the worst offenders is fleece, a plastic-based mostly, fluffy fabric.

One particular of the major means fibers enter the natural environment is by means of the rinse h2o of washing machines. Judith Weis, a retired maritime biology professor from Rutgers College in New Jersey, has analyzed this phenomenon extensively. Wastewater that goes into public sewer devices is filtered out of the water and into a sludge, a byproduct of cure. This filtering captures about 90{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} of microfibers, but, specified the monumental volume of these fibers, that even now leaves a ton of fibers in the addressed h2o, which is sooner or later released into waterways.

A lot more alarming, sludge may well be unfold on land, Weis mentioned. If spread on farmland, it can enter farm crops through their ordinary uptake of vitamins from the soil. If spread on other lands, it can enter the bodies of bugs, worms, and birds and into the open air.

“You have just moved the pollution from a person position to a further,” Weis explained.

Researchers really do not know the impact of microplastics on animals, individuals, or the natural environment. “We can only guess,” Weis said.

At URI, an interdepartmental team of about 50 lecturers are element of a “laboratory without walls” that is doing work on a wide variety of interdisciplinary responsibilities to have an understanding of and lessen this kind of air pollution. They are sampling the waters of Narragansett Bay, feeding microplastic fibers to oysters and sea urchins, figuring out how to change plastic squander to fibers at marketplace-aggressive prices, and devising marketing and advertising strategies to educate the public and to persuade people to obtain fewer and sturdier clothing.

In the company realm, Rhode Island Commerce has provided a grant to U.S. Extruders in Westerly to experiment with producing plastic fibers from plastic fishing nets. A trade team, the Rhode Island Textile Innovation Network, is doing the job with Polaris MEP, an market advisor, to knit together the different players in the point out that could assistance create a circular textile economy in which character-harming plastic squander is captured and transformed into new solutions.

Much more than one observer has said this is basic operate for the Ocean State. The Industrial Revolution was launched in The us when Englishman Samuel Slater smuggled the strategies for a textile mill out of England and constructed Slater Mill in Pawtucket in 1793. Now, far more than 70 textile companies are operating in Rhode Island, stated Peter Snyder, vice president for investigation and financial growth at URI.

Also, the wellness of Narragansett Bay and the wildlife it supports are a significant problem for all Rhode Islanders.

Bide, of URI, mentioned the evolution of textiles as today’s new pollution get worried — on scientists’ radar for only about a ten years — follows the complex and financial developments at function in The usa across the a long time. Up to the 1900s, textiles were being created of all-natural fibers this sort of as cotton and wool. The early 20th century introduced the creation of artificial nitrogen fertilizer, followed by nylon as the first oil-primarily based synthetic fiber, then followed by polyester and other synthetic products.

The sequence proceeds by the 20th century with low-priced oil for the development of polyester, successful equipment for creating low cost fabrics, heaps of garments sewn by reduced-wage personnel in the Third World, major to less costly clothing and a quickly-fashion marketplace that flogs consumers into much more paying for.

“Instead of get, maintain, mend, it grew to become purchase, throw away, and invest in more,” Bide stated.

The populace of the United States has quadrupled considering that 1900, Bide claimed, when textile use has gone up 30-fold. At current, the world use of clothing is much more than 30 pounds per individual each year. In the United States, the determine is far more than 100 lbs. Most of it is polyester.

Assistant professor Izabel Ciesielska-Wrobel of the textiles office at URI is operating on a model of a alternative underneath a job titled “Conversion of Plastic Squander into Economically Viable Filaments and Fibers.” The venture received underway just before she joined URI, while she was functioning for Luna Innovations of Virginia. Income from the U.S. Section of Strength obtained the challenge rolling.

At URI, Ciesielska-Wrobel’s job acquired a $186,000 micro compounder. The machine commences with waste plastic, then melts it and extrudes a extremely thin plastic filament. (Extrude is to develop a merchandise by pushing a thing by way of an opening. Consider generating selfmade pasta, or the traditional Play-Doh toy in which a load of Engage in-Doh in a hopper is pushed by way of a panel of slash-out shapes.)

Of training course, the method is not that easy, partly simply because of the assortment of polymers and additives in any plastic. “Some supplies are not admissible” into the approach, Ciesielska-Wrobel stated, “so you have to use a ton of chemistry to make them admissible.”

“This equipment offers a large amount of choices,” she explained. “Also, we are introducing characteristics to the components to make them additional interesting to probable clients.” In truth, she gives some of her monofilament solution to use in 3D printing.

Ciesielska-Wrobel explained there is a good deal of desire in the business enterprise globe in changing waste plastic to usable filaments and fibers. She has labored to some degree with OceanWorks, a California-based mostly enterprise with an place of work in Boston, which, she stated, collects trash plastic from all over the environment, and then separates and procedures it into usable plastic pellets. She mentioned it is challenging to get in contact with OceanWorks in recent months, implying to her that its enterprise is booming.

“My target is to market this plan everywhere and to attempt to implement it in each and every attainable way that I can,” she stated.

Comparable experimentation — by means of a task called “Fishing for Solutions” — is now likely on at U.S. Extruders, with assistance from the $43,000 Commerce grant. The enterprise builds extruding machines that, in turn, are utilised by other manufacturers to extrude products and solutions, these as professional medical tubing. Enterprise development officer John Riendeau said the company’s proprietor, Dan Schilke, was disturbed by the small level of recycling in the United States and decided to do the job on a remedy.

The business made the decision, Riendeau said, “to do a little consultant example of recycling some thing that has not been recycling in the past” — that is, fishing nets, which are generally plastic except for some removable elements of steel and rubber.

“The idea was to acquire an stop-of-life merchandise and switch it into portion of the round financial state,” he extra.

U.S. Extruders obtains scraps of fishing nets from Remarkable Trawl and Trawlworks, net companies in Narragansett, that are byproducts of production. The course of action features separating the steel and rubber, cleaning the nets, shredding and granulating the plastic, and generating plastic pellets to be offered to a wide variety of brands of all kinds of products and solutions. The very important problem, Riendeau claimed, is no matter if the value of manufacturing the recycled plastic can contend with the charge of building and shopping for virgin plastic.

Study of the amount and outcome of microplastics in the environment is reasonably young, and experts, which includes marine biologists, are working with specific logistical difficulties.

Andrew Davies and Coleen Suckling are associate and assistant professors, respectively, at URI, and they are finding out plastic particles in Narragansett Bay as a result of the Ocean State Initiative for Marine Plastics.

A 2020 Rhode Island Sea Grant challenge has permitted them to do area trawling of the bay. The do the job is difficult, explained Davies, because of the numerous distinct types of particles in the water, like plastic, that create a “noisy matrix” that is really hard to form by. Also, different plastics have unique densities and may well behave in a different way in water. At this early phase, their research has yielded number of conclusions.

Researchers also are learning the presence of microplastics on the flooring of the bay, in sediments, which in the long run seize an estimated 70{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} of all microplastics that enter waterways, in accordance to Kay Ho, study scientist for the Environmental Protection Company who is doing the job on sediment investigate in Narragansett Bay. Ho stated maritime researchers uncover microplastic sediments “everywhere we glance,” but the effects of this pollution are even now primarily unidentified.

Weis, of Rutgers University, mentioned the science of accumulating and examining microplastics and microfibers in the natural environment is fraught with challenges and inconsistencies. In a paper Weis co-wrote with Francesca De Falco, a member of the University of Organic and Maritime Sciences at the University of Plymouth in England, Weis observed some researchers accumulate samples with styles of nets that permit very long slim fibers to escape, resulting in a really serious undercount of fibers. “Grab samples” of total drinking water might get a far more accurate count, but they are unable to be usefully as opposed to samples captured in nets. Laboratory studies that use purchased samples of microplastic beads mismatch, in various methods, the ailments in the purely natural environment.

Some actions that Weis and De Falco recommend to seize microplastic fibers from just the confined world of garments would call for a large amount of customer education and actions adjust. These would include things like acquiring clothing with tight weave washing outfits in total masses, preferably in a front-loading equipment (to lessen agitation) working with fewer detergent drying outfits on a line rather of in a clothing dryer. Washing devices with developed-in filters that can seize microfibers do exist, and, in point, will be mandated in all new washing machines sold in France in the next handful of several years. Meanwhile, these wonderful-grain filters can be acquired and retrofitted onto current washing equipment, Weis claimed. Just one merchandise is the Lint LUV-R.

Karl Aspelund, affiliate professor and chairman of the Division of Textiles, Fashion Merchandising and Style and design at URI, emphasised that all the initiatives described right here — from combing the bay flooring to spinning recycled plastic into yarns — are matters that experts previously know how to do.

“We don’t have to invent anything to make all of this come about,” Aspelund claimed. “This is not a thing we have to appear up with.” The process, which URI is supporting to get the job done on, is “getting individuals to commence doing the job together.”