Recycling cellulose includes making a pulp that can then be made use of to make new fibres.Credit: Mikko Raskinen

Sonja Salmon is a large enthusiast of cellulose, and that is why she would like to demolish it. “I appreciate cellulose,” she says. “I’m ripping cellulose apart simply because I enjoy it.”

She’s also pulling it aside since the polymer, which is discovered normally in wooden and cotton, accounts for one-quarter of all the fibres utilized in textile producing. That signifies any energy to recycle clothes and cloth to retain them aspect of the round overall economy for as long as attainable has to incorporate ways to deal with all that cellulose.

Salmon, a polymer scientist at Wilson College or university of Textiles, North Carolina Condition College in Raleigh, is working on breaking down the cellulose from discarded textiles and reusing it. Many garments materials are a blend of 50 percent polyester and 50 {05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} cotton — person fibres of cotton and polyester are twisted tightly close to one particular another, developing a yarn that is then woven or knitted into a garment. Having that composition aside mechanically is hard, so as a substitute Salmon treats it with cellulases, a team of enzymes that split up the cellulose. “We can chew it up into small ample molecules and fragments that it will in fact drop out of the rest of the cloth structure,” Salmon claims.

Component of Character Outlook: The round financial state

Her focus is on characterizing the material that comes out of the breakdown system and doing the job out what it could possibly best be utilized for. For instance, the enzymes crack down the cellulose into glucose, which could be applied as a feedstock for generating biofuel. They also go away guiding small chunks of cotton fibre that could offer lightweight reinforcement for concrete. “Even however the cotton fibre will no for a longer period be very long plenty of to right spin it again into a yarn, we imagine the product has benefit,” Salmon says.

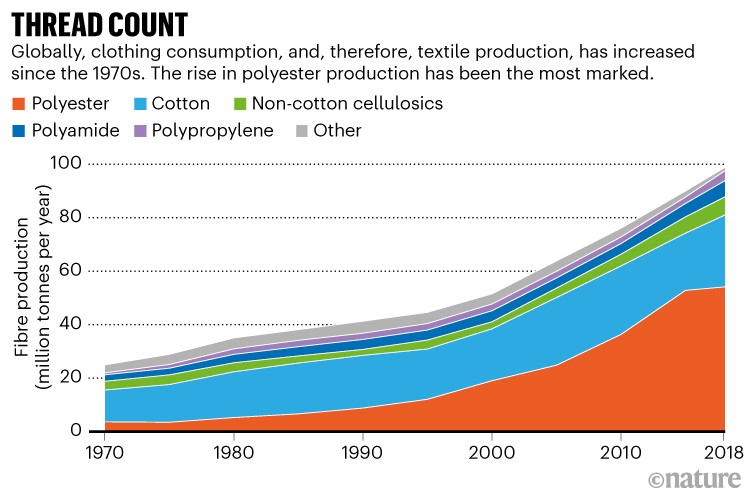

This way of pondering is a big modify from how old clothes and textiles, this sort of as upholstery materials and carpeting, are at the moment dealt with. Globally, only 13{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} of the substance that goes into building apparel is recycled, according to the Ellen MacArthur Basis, an firm in Cowes, United kingdom, that encourages the round financial system. Most textile squander — an estimated 92 million tonnes from the vogue sector on your own — created each individual year winds up buried or incinerated. “We throw stuff absent into landfill and we’re dealing with it like rubbish,” Salmon claims. “We’re not on the lookout on it as a little something that is truly a raw substance that could be reused.” The US Environmental Protection Agency believed that, in the United States in 2018, the average person threw absent 47 kilograms of textiles. About three-quarters of that— 36 kg — is clothes and footwear, although the rest is mainly towels, bedding, furnishings materials and carpets. Meanwhile, methods are expended to create virgin material (see ‘Thread count’) — h2o and land to grow additional cotton, and petroleum to make more polyesters (see ‘Recovering polyester’).

Supply: K. Niinimäki et al. Nature Rev. Earth Environ. 1, 189–200 (2020).

To counter all that squander, researchers and start off-up firms are producing techniques to get better and reuse the substance. Equivalent to Salmon, considerably of their focus is on chemical recycling, in which the content is damaged down into its building blocks and utilized to create new components, together with fibres that can be woven into new outfits. The challenges lie in building the procedures for these kinds of procedure. They have to be functional, but they also have to be at minimum as cost-helpful as simply just building new fibres.

Spinning new threads

In addition to the organic cellulose fibres from cotton, some textiles involve human-built cellulosic fibres. These fibres are derived from wood-pulp cellulose and can be employed to make elements this sort of as viscose (rayon) and a equivalent material termed lyocell. Cellulosic fibres make up all-around 6{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} of all textile fibres produced, according to the Textile Trade in Lamesa, Texas — a non-profit corporation that promotes environmentally pleasant resources.

A variation on the lyocell-manufacturing approach is getting utilized to the textile-squander issue by Evrnu, a commence-up in Seattle, Washington. One particular big improve the company has produced to the procedure is it works by using discarded textiles, instead of wood, as the resource of its cellulose. Its also tweaked the process to generate a fibre that the firm’s co-founder and president Christopher Stanev suggests is remarkable to both of those other cellulosics and to cotton, and that can be recycled additional occasions. “We can make much more robust fibre working with cotton than the a single coming from wooden pulp,” says Stanev, a textile engineer.

In the very same way as the common lyocell process, the uncooked substance is addressed with N-methylmorpholine N-oxide (NMMO), an natural compound that dissolves cellulose. This produces a thick pulp that is then filtered. At this place, the traditional procedure would involve the cellulose becoming extruded as a result of a machine termed a spinneret — first into air, and then into a coagulation tub of typically h2o in which the materials solidifies into fibre. Evrnu, nevertheless, turns the cellulose molecules into liquid crystals just before they are extruded, letting them to align with every single other and deliver a additional crystalline fibre composition.

“By doing that and having pretty a crystalline firm, you can improve the power and you can also engineer the performance of this fibre,” Stanev says. He states the fibre is about 20{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} more robust than conventional lyocell, which by itself is more robust than cotton.

That high quality translates into a for a longer time life span for a material made from the fibre, as well as a fibre that can be reconstituted many moments. Each time the molecules are operate by way of the recycling process, they grow to be shorter and thinner. But because they commence out much better, Stanev suggests, the exact material should be equipped to be reconstituted at minimum 5 periods just before it turns into weaker than virgin cotton fibre some tests in the company’s laboratory display that the substance can be recycled up to ten occasions. Which is extra than is achievable for paper, which can be recycled 5–7 times right before the fibres turn into way too limited to make a viable new merchandise.

Evrnu is managing a pilot venture at associate organizations in Germany and in other places in the United States to demonstrate that its method can deliver fabric. It hopes that a much larger textile organization will then want to license the technology. For now, it is making use of NMMO because the compound is easily accessible, but Stanev hopes to inevitably switch to an ionic liquid — a salt that is liquid beneath 100 °C — which is more chemically secure than NMMO and much more tolerant of contaminants. The firm has not yet optimized any such liquids for the creation approach.

More from Mother nature Outlooks

A Finnish business, however, is operating with an ionic liquid produced by one particular of its founders, bodily chemist Herbert Sixta at Aalto College in Espoo, Finland. The liquid utilised by Ioncell — the title of both the business and the system — is a superbase, a really alkaline substance that breaks the hydrogen bonds in the cellulose molecules. In the exact way as when working with NMMO, that procedure makes a pulp that can be fed through a spinneret to make a new cellulose fibre. NMMO tends to be unstable and requires the addition of buffer options, but the ionic liquid does not. Sixta says his ionic liquid is also totally recyclable, making the method environmentally friendly as well as producing fibres with much better mechanical properties than cotton.

The Ioncell course of action can use wooden pulp, which Sixta says counts as part of a round economic climate due to the fact the raw materials will come from Finland’s sustainable forests — these are managed in these a way that growth outpaces the amount taken off. “Our college has a big team in textile structure, so we can take care of wooden, generate pulp, transform it to fibres, transform it to yarns, convert it to materials, structure clothing, and display the outfits in vogue displays,” Sixta suggests. The system can also accept textile waste, turning old clothing into new clothes. Ioncell has built a pilot plant, with the target of assessing how well its process is effective in the real globe in about two several years.

A make any difference of price tag

Though complex issues abound, the key barrier to prevalent textile recycling might be financial, states products engineer Youjiang Wang at the Georgia Institute of Engineering in Atlanta. “Most of the resources are not that precious,” Wang claims. It’s so cheap to generate polyester, cotton and other fabrics that there’s very little financial gain margin except the recycling processes are really cheap.

There’s also a absence of infrastructure for amassing and sorting utilised textiles, beyond a few personal garments-donation teams. And the sophisticated mixture of elements in a piece of garments — not just distinct all-natural and synthetic fibres, but also dyes and chemical coatings, buttons and zips, and any non-woven additions such as leather or latex — need to be separated for individual parts to be processed.

Policymakers really should consider recycling that turns utilised garments not into new garments but into other useful — if lower worth — items, Wang argues. Fibres may be shredded for use as soil stabilizers, for occasion, or cellulose damaged down into glucose that can be turned into gas. Even burning polyester for electricity is preferable to pulling much more petroleum out of the floor to deliver electrical power. “That doesn’t audio pretty large tech, but all round, you do get appreciable profit from that,” Wang suggests.

The circular financial state should be viewed as a way to lessen as a great deal as achievable the development of virgin substance when other goods can be reused, Wang claims. “If you really want to make recycling greater for the natural environment, not just for the sake of publicity, then we have to have to establish additional systems so that you can use as a lot of what you gather as attainable,” he claims. “That would make the all round circle much more round.”