Graphene has demonstrated to be a recreation-changer in the textile sector, which is why a number of sporting activities and clothing makes are performing with graphene suppliers to produce graphene-enriched fabrics.

Chosen by much more and more specialist and beginner sportspeople, this clothing delivers functional, gentle and powerful products with interesting thermal and conductivity attributes. Some Olympian athletes in Tokyo 2020 wore graphene fabrics for their comfort and light-weight attributes.

Graphene is an excellent thermal conductor, thus suitable for heated winter season garments. Graphene preserves the heat in chilly temperature and expels heat in warm surroundings. Graphene fibres are also waterproof, as a result acceptable solutions for neoprene wetsuits and for swimwear.

The textile business can also acquire edge of graphene’s properties to make wearable electronics, which can detect, analyse and transmit information about the body and ambient details, and can have everyday living-changing programs in drugs, athletics and other fields.

Here are some illustrations of textiles with graphene that are either accessible on the industry, or in enhancement.

A new sporting expertise for warmth and dry ease and comfort all through sports activities

World sportswear model Umbro built-in Graphene Flagship Husband or wife Versarien’s Graphene-Have on™ technological know-how into its 2023 spring/summer time collection’s Elite Professional-Teaching Kit range. Graphene-Wear™ attributes novel attributes that will permit wearers to expertise improved thermal transmittance, improved moisture administration and enhanced drying level, without having compromising air or water vapour permeability.

Not long ago, Graphene Wear™ was also licensed by the independent certification system OEKO-TEX®. Gaining OEKO-TEX® Eco Passport signifies that Graphene Wear™ is an ecologically accountable textile, meets the applicable statutory specifications and textile business benchmarks, and does not hurt human health.

An progressive coating process for skin-like feeling

Graphene Flagship Related Member Grafren AB, based in Sweden, is tests their graphene-coating method with varied textile resources. The method does not use binders, nor glue to embed the conductive parts within the material. The impressive way to incorporate graphene flakes into the depth of the fabric produces a gentle, versatile pores and skin-like item with managed electrical conductivity. Granted two patents on planning of the graphene ink and coating of the fabric, the firm has created its personal unique gear for graphene coating and at existing can deal with materials as broad as two metres, in roll-to-roll mode.

The company has 3 graphene textile solutions in the pipeline: electrically heatable textiles (G-Heatex) completely ready for commercialisation, ultra-lightweight camouflage garments and tension checking materials for digital health care.

A lot more not long ago, Grafren used their solution to pure textile fibres, this sort of as flux, jute and hemp, getting favourable final results. “Once tested its performance, this can be a activity changer in the ‘green’ composites commercialisation,” says Grafren CEO Erik Khranovskyy.

Graphene-coated hemp material (credit: Grafren AB).

Conductive yarns

The researchers in the Graphene Flagship’s Flexible Electronics Operate Package deal are producing graphene-enriched conductive polyester (polyethylene terephthalate, PET) yarns. The Finnish institute VTT receives graphene-based mostly layered components from the University of Cambridge (British isles), and compounds it with PET. Later on, the content is spun and woven into a fabric by the German firm Trevira. If techno-economically productive, this product is anticipated to turn out to be a new kind of light-weight conductive yarn.

https://www.youtube.com/enjoy?v=GzIK5MaU6qs

Graphene-enriched material will work as a force sensor and was used to the shoe soles. (Credit history: Trevira)

Metals out – graphene in

As talked over in the first section of this “Materials of the future” series, graphene stands out as an exceptional different to metals. This environmentally benign, sturdy, readily readily available, and extremely conductive materials is poised to revolutionize a broad vary of purposes, particularly in the subject of wearable technologies. The electronic parts of wearable systems are now developed with metal-based inks that can be high priced (e.g., silver and gold), environmentally unfriendly and sensitive to oxidation. Changing these metals with graphene would deal with these issues and offer you numerous positive aspects, making it the best preference for the potential of wearable technologies.

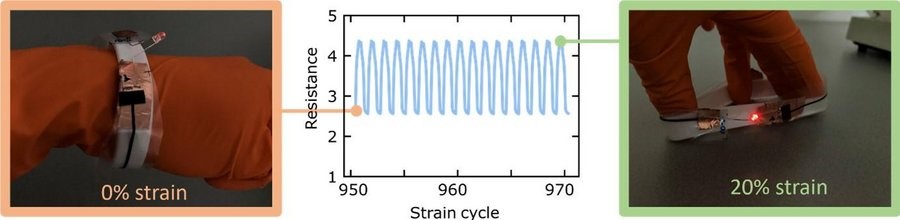

Wearable strain and stress sensors are notably appealing for wellness monitoring. For illustration, a crew led by researchers from Graphene Flagship Lover Eindhoven College of Technological innovation in the Netherlands generated a conductive ink with graphene flakes, nontoxic solvents and a stretchable thermoplastic binder of polyurethane. The ink continues to be conductive even beneath 100{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} strain and is hugely steady above 1,000 cycles of 20-50{05995459f63506108ab777298873a64e11d6b9d8e449f5580a59254103ec4a63} pressure, which corresponds to the stretching of the human skin.

Resistance vs strain curve of printed tracks on a wristband demonstrating superb stretchability and longevity of the content in excess of several cycles.

The blend of substantial conductivity, stretchability and longevity will make these conductors promising candidates for application in wristbands for sweat sensing or pulse monitoring, on-system heaters, sensible sportswear, wearable electricity resources and wearable ECG sensors. The workforce led by VTT is also doing work on a shirt for cardiac checking. This can help health care professionals to diagnose and address a variety of health and fitness ailments, though sportspeople can analyse and improve athletic effectiveness and keep track of their conditioning and progress.

Graphene-dependent dry electrodes with printed graphene for electrocardiogram (ECG) measurements is predicted to monitor human well being in a way that was not attainable in the past owing to the restrictions of the standard conductive electrodes, which are dense, non-breathable, strong and rigid (Credit rating: VTT).