Bringing collectively vital sector gamers throughout the complete textile value chain, the initiative will assist the generation of a round economy based on Worn Once again Technologies’ polymer recycling technological know-how.

To bring about a paradigm change in the style field and realise true circularity involves all users of the worth chain to be on the exact same page and functioning in direction of the similar goals, Worn Once again Technologies (WAT) states.

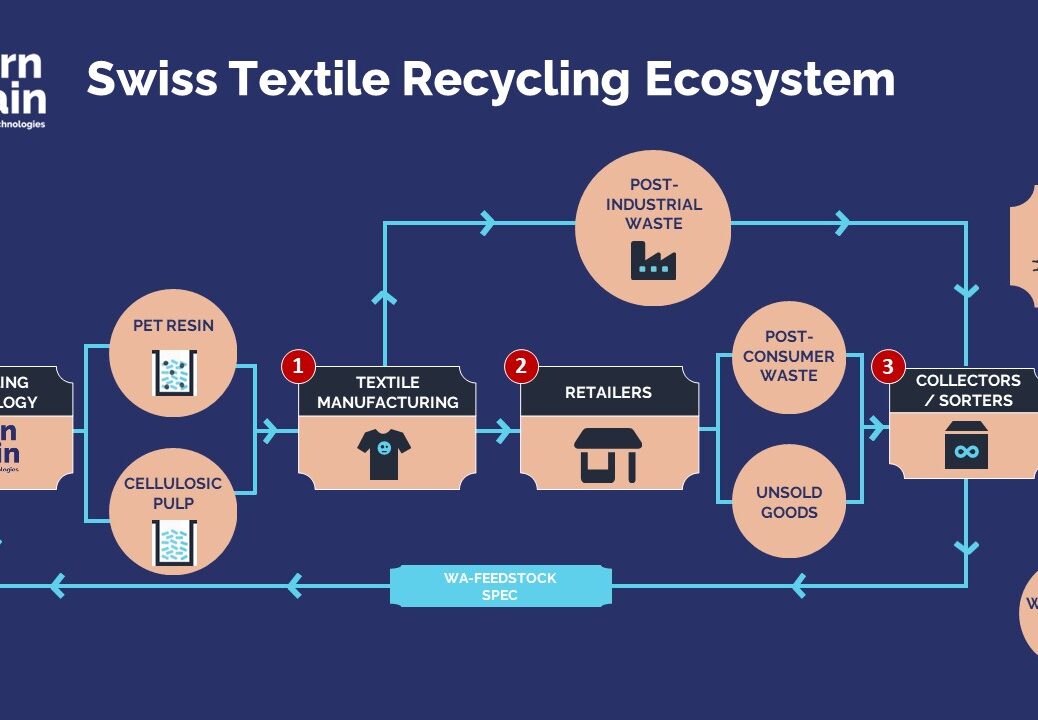

The Swiss Textile Recycling Ecosystem is a network comprising material and textile makers, waste collectors and sorters, as well as merchants, manufacturer homeowners, and technologies providers. All these events will cooperate to make their shared sustainability vision for the sector a truth.

The partners will provide various varieties of textile waste to WAT’s demonstration plant, which will process 1,000 tonnes of substance for every yr and is getting developed in close proximity to know-how scale-up associate, Sulzer Chemtech. Right after highly developed chemical processing, virgin-like recycled fibres, these kinds of as polyethylene terephthalate (PET) and cellulose, will be supplied to the same industry gamers to deliver new large-good quality fabrics.

Extra specifically, the consortium will be composed of WAT’s major shareholders, Sulzer, Oerlikon, and H&M Team. In addition, Rieter will guidance brief-staple spinning, Monosuisse will choose care of PET fibre generation, Coop will act as retailer, TEXAID will regulate selection, sorting and offer feedstock together with Sallmann (ISA) and Serge Ferrari – all coordinated by Swiss Textiles.

The creation of Swiss Textile Recycling Ecosystem marks a essential milestone in the upscaling of WAT’s recycling procedure technology, the company suggests. It also supports its ambition to generate a circular overall economy where non-reusable, really hard-to-recycle textiles can be reintroduced into supply chains to come to be new fibres, textiles, and other items.

The construction of Worn All over again Technologies’ 1st demonstration plant will get started this calendar year in Winterthur, Switzerland. It states this signifies a vital action to upscaling and commercialising the company’s recycling approach technological know-how.

“Launching the Swiss Textile Recycling Ecosystem is a vision coming genuine. This leading team of like-minded organisations will assistance to change the manner sector from standard, linear product or service lifecycle models to eco-conscious, circular content management,” suggests Erik Koep, CEO at Worn Again Systems. “We think that zero waste approaches can only come to be a actuality if the total sector is committed to performing as a total. We see the Ecosystem as a way to align sustainability attempts throughout the total textile price chain and as the following action toward a environmentally friendly trend industry.”

Torsten Wintergerste, chairman of Worn All over again Systems and division president at Sulzer Chemtech, adds: “We appear ahead to functioning alongside one another with all associates of the Swiss Textile Recycling Ecosystem. Their assistance is exceptionally important and their rely on in our task is considerably appreciated. The Ecosystem members will assistance our textile recycling demonstration facility by giving textile waste that can be utilized as feedstock. The collaboration will also engage in a important job in scaling up our capabilities and creating a community to support the implementation of industrial-scale crops globally.”